Case Study: Particle Detection Challenges in Pharmaceutical Cleanroom

Spurious particles can cause serious problems in the pharmaceutical industry, especially in a cleanroom environment. In fact, particles cause more delays in production output compared to machine-related problems. They contaminate the product, potentially resulting in a recall if it is not captured in quality control or discarded if it is — both of which waste resources and time.

Recalls can cause serious long-term consequences in the reputation of the pharmaceutical company by the public, regulatory agencies, and shareholders. Failure to maintain a clean environment could lead to warning letters, heavy fines, or shuttered operations by regulatory bodies.

Contamination Challenges in Pharmaceutical Cleanrooms

Pharmaceutical cleanrooms are used for manufacturing critical pharmaceutical products, including vaccines, as well as to perform biological analyses on finished pharmaceutical products. Regulatory bodies require each Quality department to deploy strict monitoring routines to ensure a contamination-free environment.

A particle counter is one monitoring technique to measure particle concentration and sizes. The results from particle counters are used to validate filtration systems and to identify contamination sources.

Quality departments measure the particle concentration daily before the start of production to ensure area cleanliness. After satisfactory results, they allow the production or analysis to begin.

Case Study: HVAC Contamination in a Cleanroom

In this case study, the routine daily particle counter check indicated an unusual concentration of particles in the cleanroom, outside acceptable levels. The Quality department didn’t allow the production process to start and mandated the cause to be identified and rectified.

The production department submitted a Complaint Action request to the HVAC department, the responsible department for rectifying issues such as this. The HVAC department thoroughly inspected all the sections leading to the cleanroom such as the connecting ducts, grills, blower fan, filter housing and filters.

The HVAC department discovered that the filter was not properly filtering the particles from intake, and in fact was generating additional particles. The filter was replaced, and the associated grill and connecting ductwork was cleaned to prevent any accumulated particles from spreading into the cleanroom area.

Although the Quality department performed its duty well and identified the particle concentration before the production process started, concerns remain:

- The process is dependent on satisfactory particle counter performance. If there were a defect in the particle counter, the particles would be left unidentified. This would negatively impact the product and could harm the manufacturer’s credibility and market share.

- Relying on the daily inspection caused a sudden, unplanned breakdown in the manufacturing process, causing a delay in the entire production schedule. This can be catastrophic on peak-requirement days and could cause the manufacturer to lose market share and clientele.

- If spare parts are not available, then maintenance activity could be delayed further.

- Relying on a morning inspection means the production the prior day may have been impacted by increasing particles, and cause additional costs for intense quality control and\or loss of product.

What Is a Particle Counter?

Particle monitoring is done by particle counters that detect the concentration of the particles in a given area. There can be different specifications for different counters, but they can measure the particle concentration from 0.05 μm to several hundred micrometers. There are different types of particle counters including those listed below[1]:

- Optical Particle Counter: The particles in the air scatter the light generated within the counter, which is sensed and measured by the detector.

- Laser Particle Counter: Similar in principle to the Optical Counter, with a laser as the light source. When the laser beam is dispersed by particles, photo detectors sense and measure this disruption.

- Filtration Counters: These counters use filtration media to collect particles. These counters are only used to detect the presence of particles and cannot be used to classify particles according to their sizes.

Standards for Cleanroom Cleanliness

The ISO standard for cleanroom cleanliness is ISO 14644-1:2015. According to this standard, the size and quantity of particles sizes depends on the cleanroom classification. The following chart shows the maximum concentration limits for each ISO cleanroom classification:

|

ISO classification no. (N) |

Maximum concentration limits (particles/m3 of air) for particles equal to and larger than the considered sizes shown below |

|||||

|

. |

0.1 μm |

0.2 μm |

0.3 μm |

0.5 μm |

1 μm |

5 μm |

|

ISO class 1 |

10 |

2 |

- |

- |

- |

- |

|

ISO class 2 |

100 |

24 |

10 |

4 |

- |

- |

|

ISO class 3 |

1,000 |

237 |

102 |

35 |

8 |

- |

|

ISO class 4 |

10,000 |

2,370 |

1,020 |

352 |

83 |

- |

|

ISO class 5 |

100,000 |

23,700 |

10,200 |

3,520 |

832 |

29 |

|

ISO class 6 |

1,000,000 |

237,000 |

102,000 |

35,200 |

8,320 |

293 |

|

ISO class 7 |

- |

- |

- |

352,000 |

83,200 |

2,930 |

|

ISO class 8 |

- |

- |

- |

3,520,000 |

832,000 |

29,300 |

|

ISO class 9 |

- |

- |

- |

35,200,000 |

8,320,000 |

293,000 |

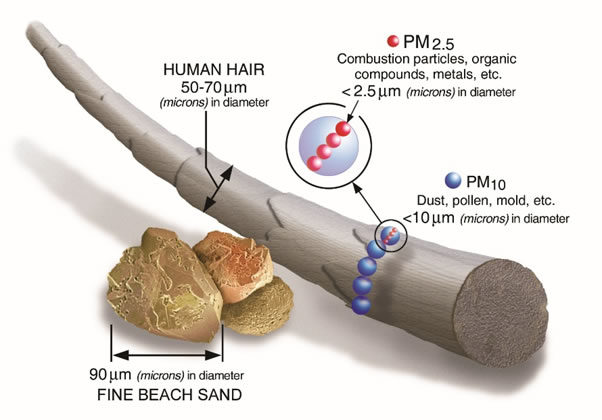

The scale of the particles referenced above can be difficult to visualize, so the US Environmental Protection Agency (EPA) published this illustration to help: [3] This standard is not used to characterize different particle types such as Physical, chemical or radiological.[2]

[3]

[3]

Cleanroom Wipes for Particulate Detection

When a particle counter is not readily available, a quick and easy way to detect particle presence in a cleanroom environment is to use wipes.

Wipes are commonly used for cleaning aseptic and cleanroom areas. The material of these wipes can absorb the particles and contaminants from the surface of the desired object. However, another advantage is that they can be a handy tool to detect particles. If, after cleaning the surface, wipes are dirty it means cleaning was successful but also indicates the presence of particles. In this way, wipes can expediently check the integrity of the filtration or HVAC system.

Although common wipes can detect particles of any type and size, they are unable to detect particles that are light or white in color, which could include fiber, lint or filter particles. These shades of particles blend in with the light-colored material forming common wipes.

Light-colored particle contaminants can be easily detected by using dark-colored wipes such as Coventry Poly Double-Onyx ESD Wipes. Much like common wipes, they absorb foreign particles while cleaning surfaces. They are manufactured of second-generation no-run monofilament polyester knit black material. These wipes can easily detect light-colored particles such as soil, dust and fiber particles.

|

|

|

|

White polyester wipe hides contamination because of lack of contrast. |

Close-up of contamination on the black wipe material. |

Additional advantages of Coventry Poly Double-Onyx ESD Wipes:

- Can be used in any controlled environment industry such as pharmaceuticals, cleanroom, and semiconductor

- High durability for cleaning rough, abrasive, or irregular surfaces

- Does not release loose fibers

- Excellent solvent and acid resistance

- Low ionic, nonvolatile residue and particle contamination

- Good absorbency

Wipes are a standard and common method of cleaning contaminants from surfaces but can also be used to expediently test for particles in a cleanroom environment. Commonly, wipes are made up of light-colored material that could detect dark-colored particles. But in order to detect light-colored contamination, using dark-colored wipes such as Coventry Poly Double-Onyx ESD Wipes can be added to the cleanroom toolkit.

For more information, contact your Coventry cleanroom application specialist at 678-928-6534 or askchemtronics@chemtronics.com.