Overcoat Repair

Contact Us

Overcoat Repair

*=required field

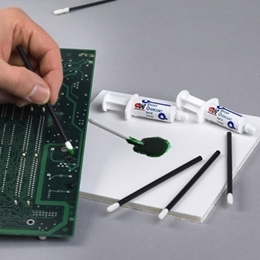

Repair Scratches, Chips & Even Structural Cracks in PCB Solder Resist Overcoat

Repair scratches and chips in PCB solder resist with Overcoat Pens. They are available in multiple colors, to match the current overcoat as much as possible. Overcoat Epoxy provides a rugged repairs that can actually reinforce PCB areas with more structural cracks.

CircuitWorks® brand’s comprehensive line of conveniently packaged and precision dispensing rework and repair products makes circuit board repair and prototyping faster, easier and more accurate. Advanced-formula materials packaged in unique delivery systems ensure superior performance and pinpoint accuracy. The full range of products meets all of the