How Coventry Wipes Reduced Contamination in a Medical Device Manufacturing Process by 90%

Many times simple changes can yield huge results, today we'll review how we helped a catheter manufacturer reduce contamination in their manufacturing process by 90%. They achieved this result without overhauling their entire process, they just switched to our Coventry wipes.

Coventry Wipes

Make a difference in cleanroom processes:

- Eliminated 90% of fiber and particle contamination on final products

- Raised cleanroom level to ISO Class 5

Take a look at their story below, but remember that results like these are not one-offs, they can be duplicated. View our selection of cleanroom wipes and get in touch with us so we can improve your process and increase your bottom line.

Contamination Affects Bottom Line, Hurts Credibility, and Puts Patients at Risk

A large cardiac catheter manufacturer had been put on warning by the FDA due to fiber and particle contamination issues. The contamination was appearing on a significant number of parts and within their final packaging.

The standard requirement is zero visible particles and fibers. In addition to FDA scrutiny, these particles and fiber contaminants contributed to a high rejection rate, high rework rate, and returns; which had become a needless operational and financial burden for the company. Most importantly, the company reputation was being damaged in the marketplace and patients were put at potential risk.

The manufacturer has decided on a long-term strategy to improve overall cleanliness and raise the level of the cleanroom to ISO Class 5. We tackled the problem by doing the following:

1. Identify the source(s) of the fibers

2. Remove or remediate the source

3. Increase overall process control, including vigilance.

Device and workspace cleaning was being performed with isopropyl alcohol, with high purity and lot traceable ACS Reagent grade. It was dispensed from larger bottles into small containers at several workstations. The wipes were ‘lint-free’ wipes and made of a non-woven, hydro-entangled, polyester/cellulose blend. They were packaged for cleanroom use and purchased from a reputable cleanroom consumable supplier.

These wipes provided some absorbency and moderate strength. They were also versatile and economical to use on benches, equipment, and tools. The non-woven, lint-free wipes, however, were implicated as the primary source of the fibers.

Use Black Polyester Wipes to Test and Validate Your Process

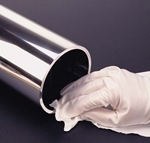

We validated our hypothesis by using Coventry™ Poly-Onyx BESD wipes to sample and validate the cleanliness of work surfaces and product in reverse of the production sequence. The Poly-Onyx wiper is black so fibers and light-scattering particles and fibers were instantly visible.

The 9” x 9” wipes were quarter folded to produce four testing surfaces. The heat sealed edges were held in the palm while the folded side was wiped on the test surfaces. Two sources were discovered. The first was a slightly abrasive surface and the second source was an area of poor laminar airflow. The original, non-woven wipes were especially susceptible to particle shedding on rough, jagged and elastomeric surfaces. Even vigorous wiping on relatively smooth surfaces and rough handling could cause small amounts of cellulose fibers to break and shed.

The solution that we offered was an upgrade to a Coventry® brand heat-sealed polyester wipe with a moderate basis weight. The toughness and consistency of the synthetic cleanroom polyester wipe resisted breakage and particle release. The moderate basis weight provided equal absorbency and better particle entrapment than the original non-woven. And that's how we improved their process. As we stated earlier, the results are not one-off, and they can occur in your application. Speak with one of our specialists today regarding your cleanroom manufacturing process. In the meantime, tell us what you thought of this case study. If you need more information or just have a question, post your comments below.